drop casting method

Up to 10 cash back Development of multiple-droplet drop-casting method for the fabrication of coatings and thin solid films Abstract. Due to these advantages the drop-casting method has potential for industrial applications.

Thin Film Processing Method Part 1

Drop-Casting Method to Screen RuddlesdenPopper Perovskite Formulations for Use in Solar Cells Author.

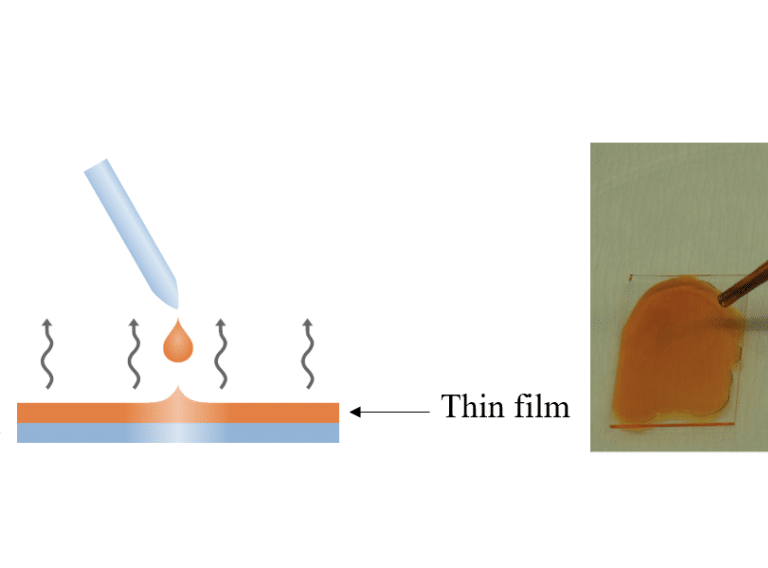

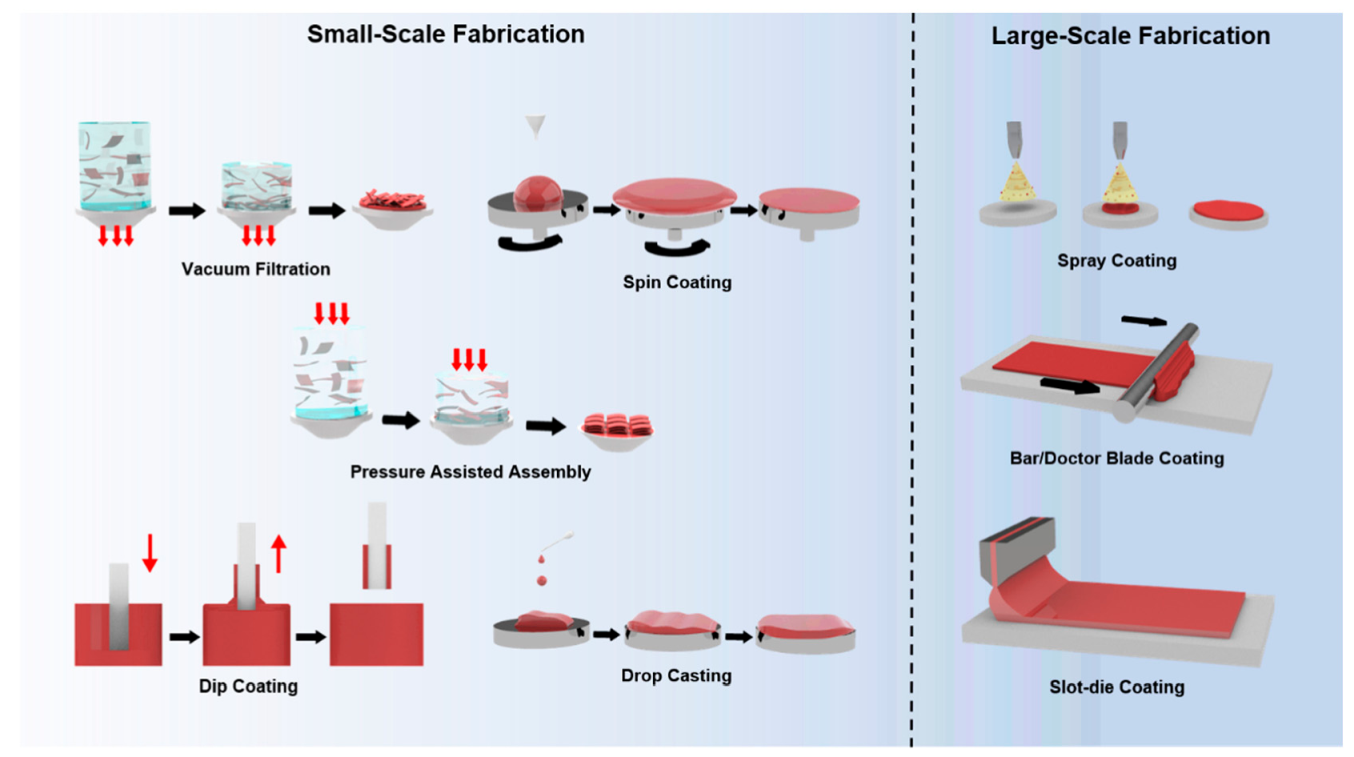

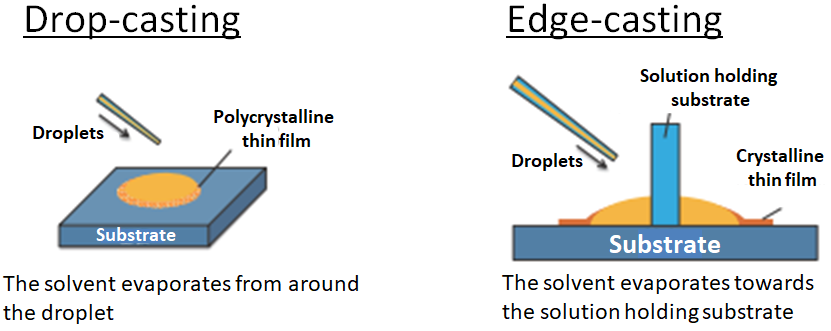

. Drop Casting Dropping of solution and spontaneous solvent evaporation Evaporation Dropping. Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes. Drop-casting is a simple alternative method for film formation that is more closely aligned to industry-relevant coating processes.

Several days elapse between each displacement and total test times exceeding one month are not uncommon. Avoid making a lot of false casts as this can spook the fish. Chuantian Zuo Andrew D.

Scully Mei Gao Source. Spray coating is a commercial and low-cost technique for the fabrication of large-area coatings and thin. For small substrates 1 cm 2 an easy and tunable deposition method is drop-casting spreading a nanoparticle dispersion over a substrate and allowing it to dry under controlled conditions ie.

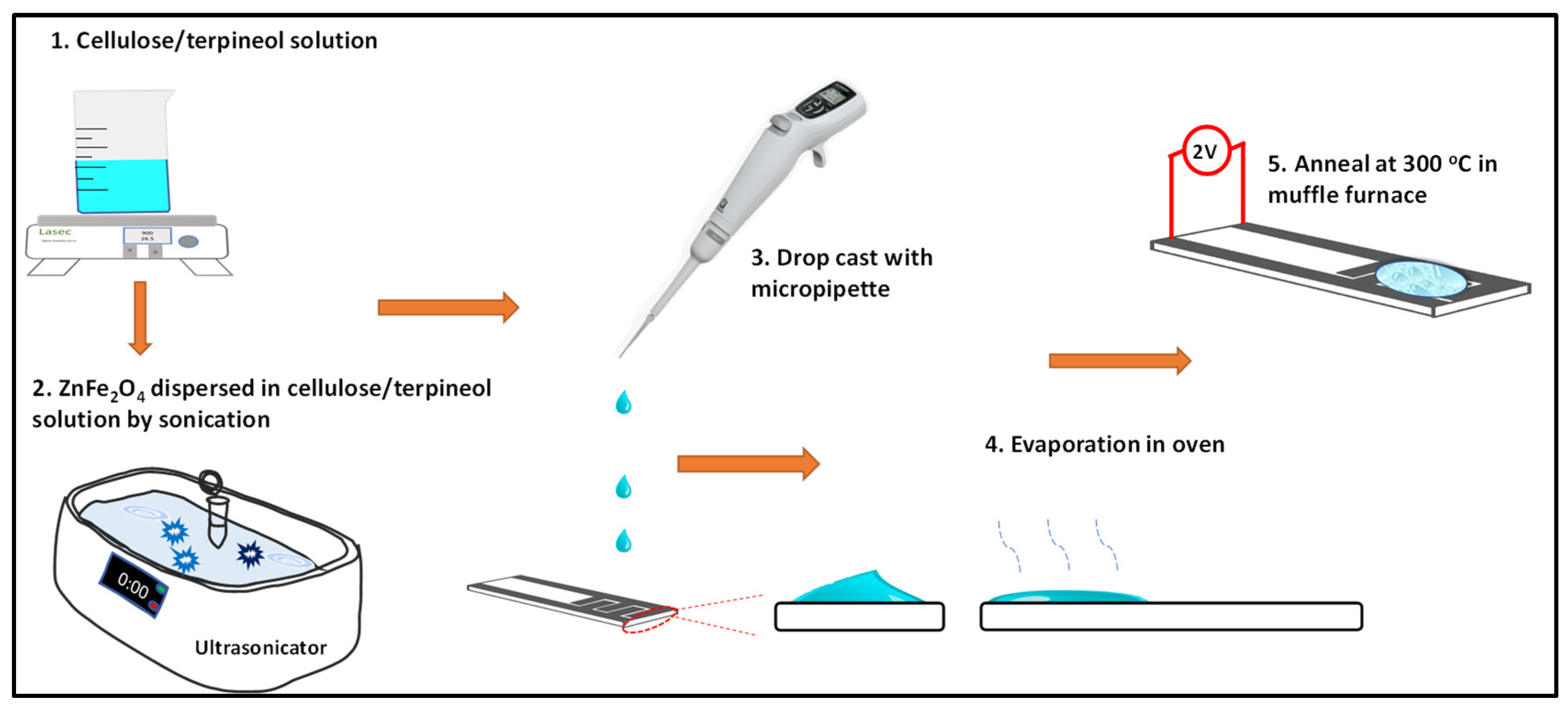

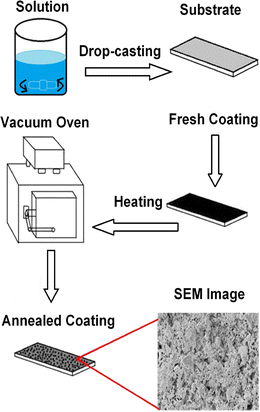

It requires a very small amount of solvent. Combination of solvents Solvents evaporation time. In the present work drop-casting was used to prepare films for screening two-dimensional RuddlesdenPopper 2DRP metalhalide perovskite formulations for potential utility in PSCs without additional processing steps such as inert-gas blowing or.

Drop coating The thickness of the film obtained is directly proportional to the concentration of the nanocomposite solution or suspension. In this paper we report on the fabrication of a large-area monolayer of SiO 2 NPs 50 nm in diameter with a high surface coverage on top of a silicon substrate using a drop. Lift your rod to keep the fly high in the water column and then drop your rod tip.

When products are not suitable for forging casting is the economic method for blank shape. Casting is the oldest metal processing process that first melting metals into liquid status then pouring metal liquid in injection moulds and cooling a while to obtain the required shape or dimensions. Wait 30 seconds and rinse with clean solvent or.

Multiple droplets formed using this method provide a distinctive environment to control the shrinkage direction and the evaporation rate of the droplets Liu et al 2014. Results obtained from these two methods are in good agreement. Langmuir-Blodgett Spray coating.

In principle film thickness depends on the volume of dispersion used and the particle concentration both of which can be easily varied. In the present work drop-casting was used to prepare films for screening two-dimensional Ruddlesden-Popper 2DRP metal-halide perovskite formulations for potential utility in PSCs without additional processing steps such as inert-gas blowing or. The most commonly used techniques for contact angle measurements are the sessile drop method and the Wil-helmy plate method.

Make a bubble of liquid on top of a surface then either. In this method a drop of liquid containing a suspension of the particles of interest is first deposited literally drop casted on the surface of the electrode to be modified ideally exclusively confined to the conductive electrode without. Quickly load your rod cast 4 to 5 feet past the fish.

The drop shot may be the most versatile finesse technique in fishing. Asked 22nd Jul 2017. A first polymer solution is added and dispersed in the first mixture to prepare a second mixture.

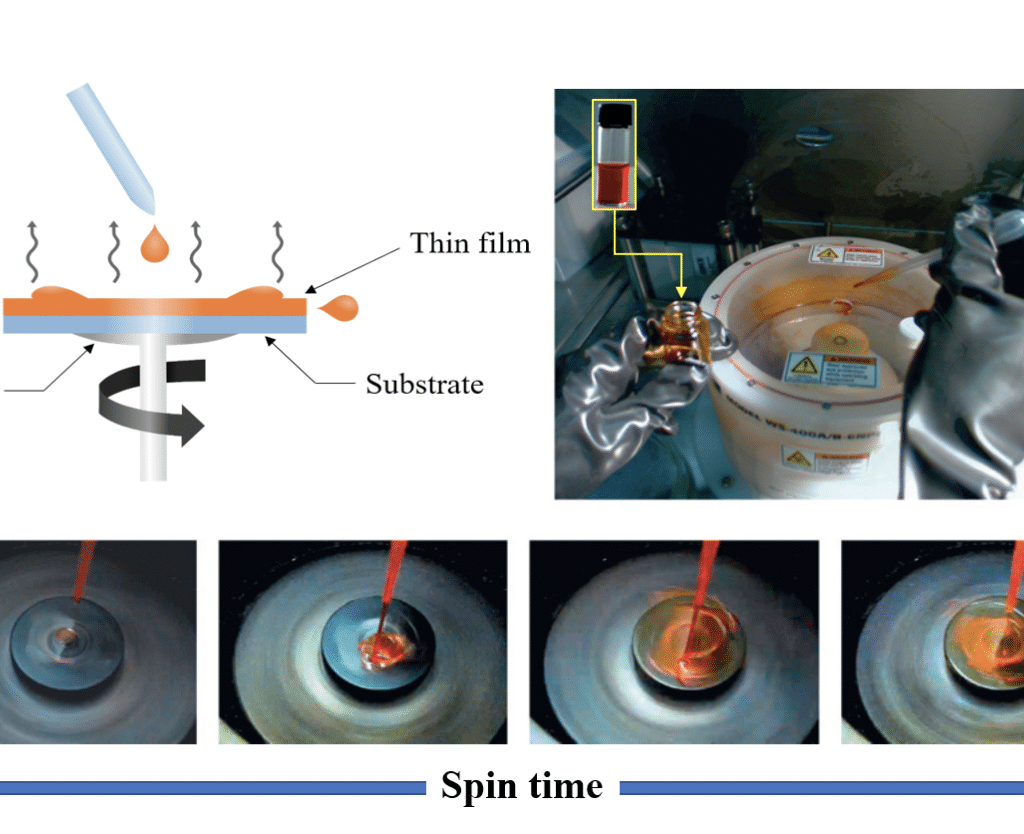

The solution containing the desired material is cast on a substrate following by the evaporation of the solvent. ACS applied materials interfaces 2021 v13 no47 pp. Dependent on many controllable parameters dωdt ω t solution viscosity.

This method is advantageous since the thickness of the polymer-coated film on the electrode can be known from the original concentration of polymer solution and droplet volumeThis technology is rather simple and there is no waste of material. The sessile drop method has several drawbacks. After casting upstream VanDam let the current usher his drop shot rig downstream.

Dip coating drop-casting spin-coating bar coating knife coating and doctor blading are individual film. In particular we note that the overwhelmingly popular approach for the preparation of PMEs is via the method of drop casting see Fig. Drop casting is a simple film-forming technique used by many research groups as it does not require specific equipment.

Deposition techniques Drop casting Spin coating Dip coating Layer-by-layer. Drop-casting is a simple cheap method and permits the formation of a monolayer over a large area. Heating of the substrate to speed up the evaporation process andor improve film morphology.

This method is called as solvent casting because the polymer is completely soluble in the solvent which ensures uniform distribution hence fulfilling one of the ideal scaffold properties. How to Execute the Drag and Drop Cast. Manuscript Generator Sentences Filter.

What is the drop casting method details advantage and disadvantage of this method and what is maximum thickness of films can be given. Depending on the depth a 316- or 14-ounce weight kept the sinker ticking lightly over the bottom. Spin Coating I Dropping on spinning substrate Film thickness.

It can be difficult. In a method for preparing a conductive polymer electrode by using drop casting conductive material is dispersed in a solvent to prepare a first mixture. Spin the chip on a spinner or.

Start in the ready position with the fly in hand and plenty of fly line un-spooled from the reel. Here are some of the most unique ways to present baits with this rig. This method is used for the formation of small coatings on small surfaces.

A second polymer solution is added and dispersed in the second mixture to prepare a third mixture. Coatings manufacturing screening solar cells spectroscopy utilities. Coatings and thin solid films may be deposited from the vapor.

This method is widely used because of low costs shorter preparation time and most importantly easy variation in reaction conditions.

Formation Of Uniform Reduced Graphene Oxide Films On Modified Pet Substrates Using Drop Casting Method Sciencedirect

A Facile Drop Casting Approach To Nanostructured Copper Oxide Painted Conductive Woven Textile As Binder Free Electrode For Improved Energy Storage Pe Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C6ta10428b

Thin Film Processing Method Part 1

Solvent Casting Technique Drop Casting Method Dip Coating Technique Film Casting Technique Polymer Coatings Technologies And Applications

Processes Free Full Text Enhanced Propanol Response Behavior Of Znfe2o4 Np Based Active Sensing Layer Induced By Film Thickness Optimization Html

A Schematic Illustration Of The Drop Casting Method And Conventional Download Scientific Diagram

Controllable Fabrication Of Oriented Micro Nanowire Arrays Of Dibenzo Tetrathiafulvalene By A Multiple Drop Casting Method Nanoscale Rsc Publishing Doi 10 1039 C3nr05680e

Schematic Diagram Of Thin Film Fabrication A Drop Casting B Spin Download Scientific Diagram

Organic Photodetectors Based On Copper Phthalocyanine Films Prepared By A Multiple Drop Casting Method Sciencedirect

A Simple Drop Casting Approach To Fabricate The Super Hydrophobic Pmma Psf Cnfs Composite Coating With Heat Wear And Corrosion Resistant Properties Springerlink

Schematic Representation Of The Drop Casting Technique Used To Deposit Download Scientific Diagram

Perovskite Deposition Using Drop Casting Technique 99 Download Scientific Diagram

Pdf Fabrication Of Silica Pmma Composite Based Superhydrophobic Coating By Drop Casting Method Semantic Scholar

Schematic Diagram To Drop Casting Method Download Scientific Diagram

Sketch Of The Drop Casting Process Is Depicted Download Scientific Diagram

Nanomaterials Free Full Text Fabrication Techniques For Graphene Oxide Based Molecular Separation Membranes Towards Industrial Application Html

Figure 3 From Comparison Of Drop Casting Vs Spray Pyrolysis Mwcnts Technique For Surface Modification Based Interdigitated Electrode Semantic Scholar

The Drop Casting Method Download Scientific Diagram

P Type Organic Semiconductors Synthesis Materials Products Laboratory Chemicals Fujifilm Wako Chemicals Europe Gmbh

0 Response to "drop casting method"

Post a Comment